Boxes – Trays – Buckets – Containers – Tubs

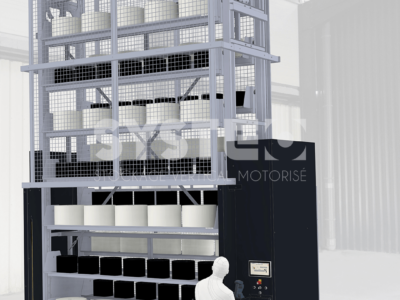

The product being stored is placed on a specially designed and sized flat-base rack. The overall capacity depends on the available length and height. Option of incorporating a drip tray for polluting liquid products (as per DRIRE requirements).

Ideal solution for reducing RSI thanks to ergonomic load picking. Compatible with loading/unloading using a load handling truck.

Storage level numbering – Cell rail – Full housing – Removable anti-theft rail – Fully enclosed rear – etc.

Depending on the design and product being stored, loading/unloading can be done manually or using suitable equipment.

Maximum weight per level : Not provided

Height : 3 to 6.5 metres high.

Maximum useable length : 4.5 m.

Linear speed : 5.00 m/min.

Control : press and hold or automated.

Power supply : 380 V – 0.55 kW to 1.1 kW

*Standard version, subject to change according to configuration

Floor sizes available – Quantitative targets to reach – Product sizes and weights (boxes, trays, tubs, etc.)

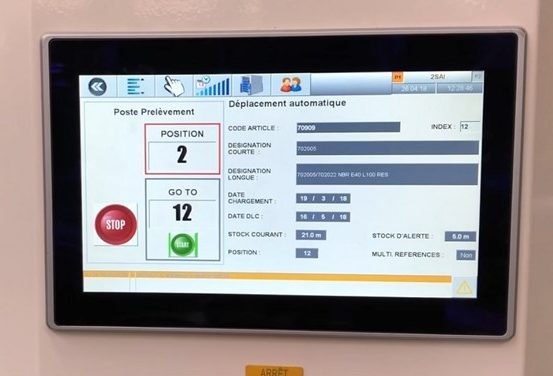

Easy to use

The default control method is pressing and holding the button to reach the desired item. The carousel can be rotated in both directions.

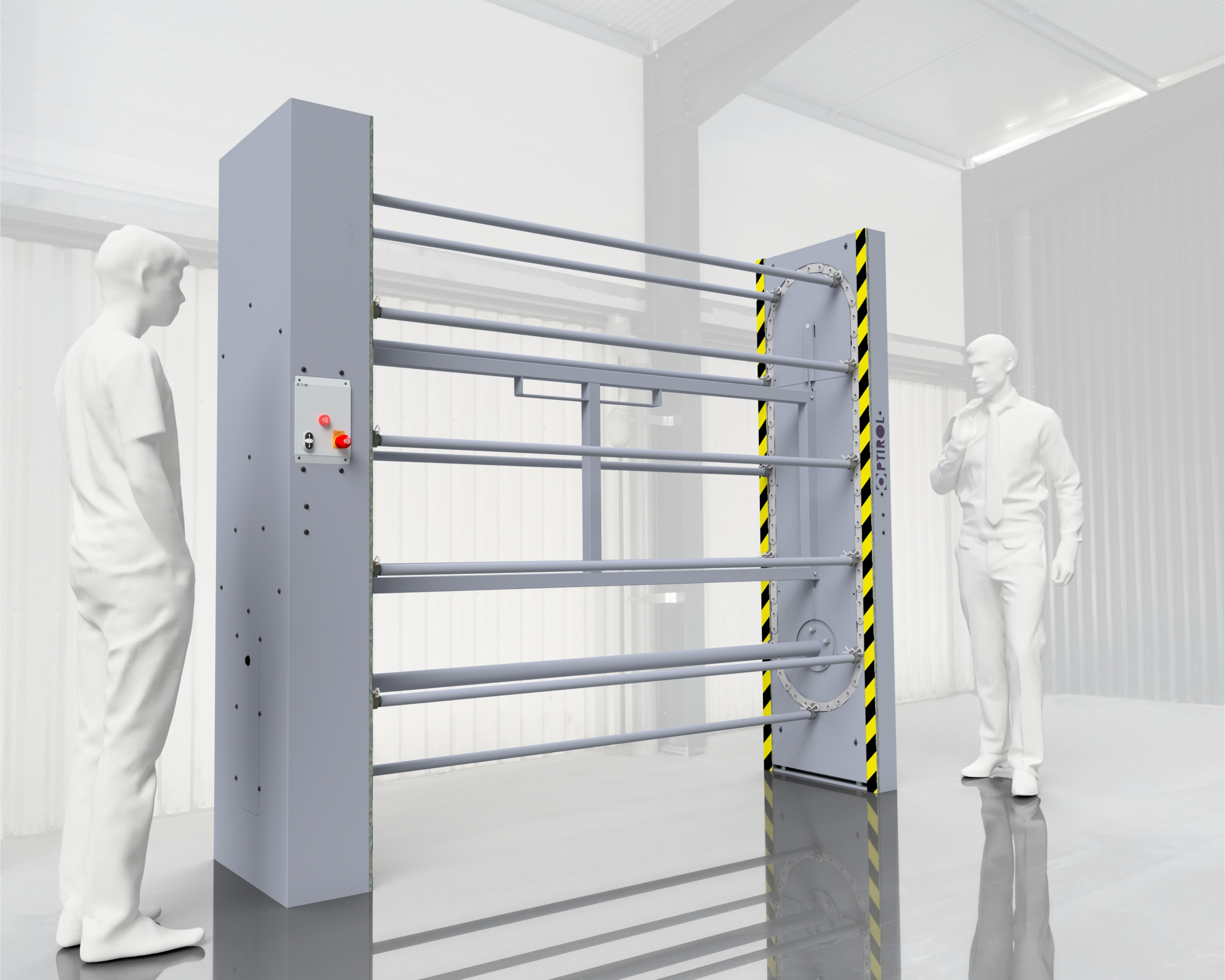

Safe to operate

No risk for your employees, with an ergonomic work height when loading and unloading

Quick access

Press and hold the button or enter the location code to quickly reach the right item

Optimised space

Easily make use of your building’s overhead space

Stock management

Makes stocktaking faster – can be integrated with ERP and WMS for optimised management.

Heavy and bulky product storage

Specific products for every application

Forward or Reverse press button

Control with tactil screen